Working Principle:

MVR is short of for (Mechanical Vapor Recompression), It uses the secondary steam and energy generated by the evaporation system itself to pass the low-grade (lower temperature and pressure) steam through the mechanical work of the steam compressor, compressing and heating into high-grade (higher temperature and pressure) steam, making the original the waste steam is reused.

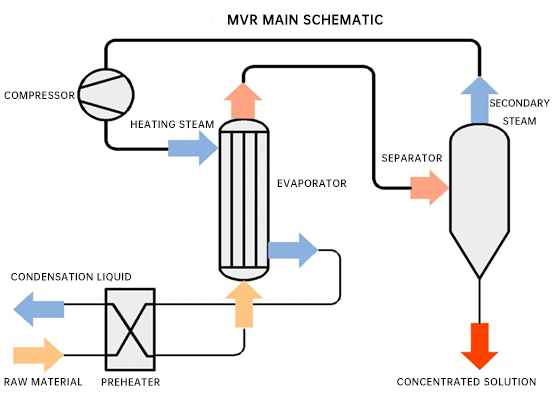

The MVR evaporator uses the secondary steam generated in the evaporator. After the steam compressor compresses and does work, the temperature and pressure increase, and the enthalpy increases, and then it is sent to the heating chamber of the evaporator as heating steam, and releases latent heat to evaporate The material liquid on the heating side of the device gets heat and then boils and vaporizes, and then produces secondary steam to the steam compressor, while the heated steam is condensed into water and discharged outside, and the above process is repeated again and again. In this way, not only the latent heat of the secondary steam is recovered, a large amount of raw steam is saved, but also the circulating cooling water required to cool the secondary steam is eliminated, which improves thermal efficiency, reduces energy consumption, reduces pollution, and achieves the purpose of energy saving.

Main Feature:

1. MVR evaporator technology is currently the most advanced evaporator technology in the world, it’s mainly using electric energy. In addition to a small amount of industrial steam heating during the start-up phase of the equipment, only clean electric power is required during normal operation, without industrial steam or a very small amount of fresh steam, which greatly reduces the operating cost of the enterprise and reduces environmental pollution, but the equipment has a large one-time investment.

2. During normal operation, the system only uses electricity and does not use steam. The energy consumption per ton of water evaporated is 15KW·h to 50KW·h, and the operating cost is low.

3. Due to the use of steam compressors to provide energy, compared with traditional evaporators, the heat transfer temperature difference is small, which is particularly suitable for heat sensitive materials and low concentration materials, greatly improving product quality, reducing the risk of scaling, and extending operation time.

4. Most of the single-stage vacuum evaporation is used. The material is evaporated at low temperature (evaporating temperature 45℃-85℃) and does not produce foam. The material liquid is uniform, does not run out, is not easy to coke, and the material is heated to less degeneration.

5. Few supporting public works. The heating chamber of the MVR is a steam condenser, it does not need a separate steam condenser and a huge circulating cooling water system, which can save more than 90% of the cooling water.

6. Compact structure, small footprint.

7. The equipment realizes automatic operation through PLC control to avoid operator error or MVR failure due to incorrect operation and ensure long-term continuous and stable operation.

The MVR evaporator can be coupled with different types of evaporators and crystallizers for continuous evaporation and crystallization. The main types are:

l MVR forced circulation evaporator.

l MVR rising film evaporator.

lMVR falling film evaporator.

lMVR split evaporator.

System Composition :

It is composed of heater, separator (crystallizer), steam compressor, vacuum pump, circulating pump, operating platform, electrical instrument control cabinet, valves, pipelines and other systems, with simple structure and small footprint.

Scope of Application:

The MVR evaporator designed by Jiangsu Heide has been widely used in the evaporation and concentration of water, dilute solution, sugar liquid and wastewater treatment in the medicine, food, chemical, light industry and other industries.

1. Evaporative concentration in chemical process, preparation of inorganic salts, recovery of valuable solvents, concentration and disinfection in food industry, etc.

2. Distillation process of chemical process.

3. Desalination.

4. Radioactive wastewater treatment.

5. Pre-concentration during evaporation and crystallization.

MVR evaporation equipment is compact, small footprint, small space required, and does not require a circulating water cooling system. It is especially suitable for existing plants that need to expand evaporation equipment for steam supply, insufficient water supply capacity, and insufficient space, or cryogenic evaporation requires chilled water in the case of condensation, it can save investment and save energy.